Green Charcoal, a partial solution to natural resource degradation in East Africa

On a worldwide basis, the destruction or degradation of forest vegetation by slash and burn agriculture and timber harvest is the largest contributor to increased CO2 emissions into the atmosphere. This is more than manufacturing emissions, machine exhaust emissions, and petrochemical by-product emissions combined. So by extension, some might say that forest resource misuse is the primary problem to be solved when looking at our efforts to reduce CO2 emissions, and thereby improve our climate change outlook.

In East Africa, a major portion of forest degradation is done by persons engaged in charcoaling. Charcoaling is a production process whereby indigenous hardwood trees and shrubs are indiscriminately harvested and put through a slow burning/drying method which results in slow burning fuelwood used for daily cooking activities by a majority of the population in both rural and urban areas.

Natural gas and other alternative resources are for the most part felt to be too inconvenient and too unaffordable. In Kenya, as within several East African countries, this harvesting, almost always done on public lands or other lands not owned by the harvester, is illegal. However, with almost no alternative(s), there is little or no enforcement.

The associated negative consequences are myriad, including habitat destruction, respiratory diseases from frequent smoke inhalation, and the undermining of the country’s revenue production by this huge underground economy not contributing to society.

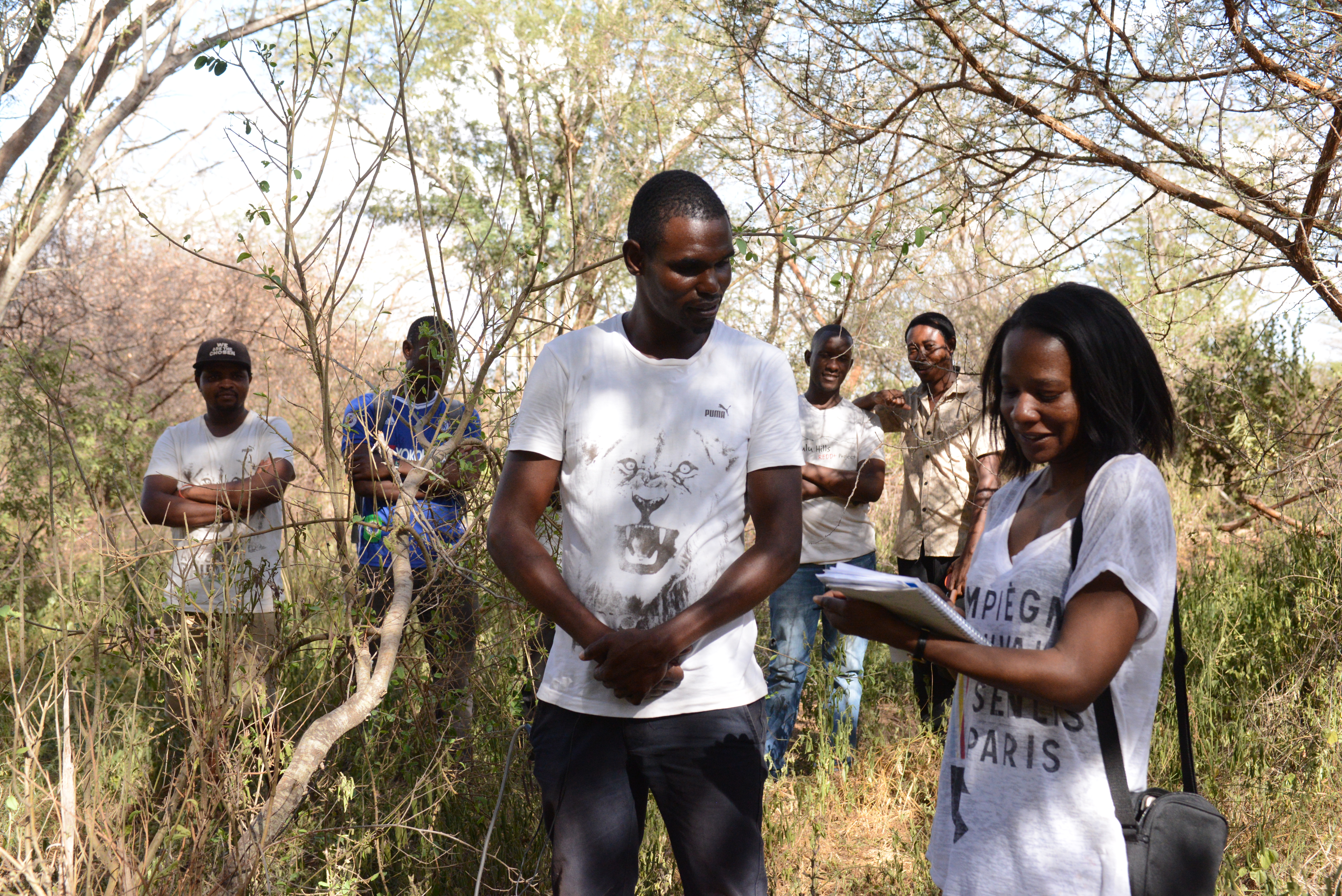

Just a few months ago we began to think about the possibility of somehow sustainably producing a legal, or “green” charcoal as not only an affordable alternative to bush charcoal, but also as a way to channel some of our community reinvestment mission of job creation for local persons. Thus was born the idea of finding a way to make better, more price-competitive cooking charcoal form sustainably grown hardwood treefarms. After much research and consultation from biomass fuel proponents from around the world, we feel we are ready to try our solution.

Small fingerling-sized hardwood branches are pruned from trees left standing to regrow another branch for harvest the following year; the branches are put through a charing process which has proved to be much more time efficient and yield efficient than the traditional bush methods, and then the finished, dried charcoal is compacted into manageable briquettes by a mechanical press after being mixed with the WWC secret sauce slurry.

The briquettes are then packaged into approximately 5 pound, 30 pound and 65 pound recyclable bags. These are ready to be affordably sold in local markets, now being arranged. We are hopeful that the marketplace embraces the product with the same enthusiasm our local workers have applied to their efforts. Further, we are hopeful this solution can be transported to the many parts of the African continent and beyond where this problem is such a burden and misfortune on the human condition.

2 Comments

Pingback:

Teddy Kinyanjui

Hi Jeremy – I am very happy to read this – great work and kudos to you and the WW team!

We have been designing a wood-oil trap for our charcoal kilns that you can use to condense most of the smoke into liquid wood vinegar and Stockholm tar. This can be used as a natural wood preservative etc. Here is a link to more info – all the best, https://www.facebook.com/media/set/?set=a.609236529117746.1073741911.199734683401268&type=1